Implementing a Powerful Energy Management System

Download a PDF version of this case study.

Discover how our partner Pluggable implemented a complete Energy Management System (EMS) for GenCell using macchina.io EDGE and REMOTE technology. In less than a year, delivered was a complete solution that autonomously manages over 30 components, provides secure remote access, and supports future IIoT applications – all while reducing hardware costs by 75%.

GenCell’s leadership highlights how this rapid development allowed them to go to market faster with a robust, scalable EMS platform. Read on to find out more about the technology behind this success.

Fueling a New Era In Humanity´s Tomorrow

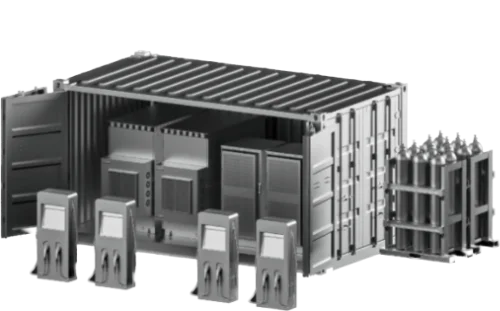

A Compact Hydrogen Fuel Cell System

In a fast-paced world, GenCell stood out with a plan to change and revolutionize clean energy. They aimed to develop a cutting-edge hydrogen fuel cell system that would give us all a better future.

This system converts hydrogen gas into electricity, providing a clean power source for applications such as electric vehicle charging, off- grid power and backup/emergency power.

We based our edge IoT on macchina.io EDGE SDK to allow rapid development and fast go-to-market. This decision has proved itself, as our development team evolved it into a full featured edge EMS platform.

Haim Moshe,

VP Customer Services GenCell

GenCell Energy Management System Requirements

EMS Data Acquisition and Decision Making

The energy management system needs to gather real-time data from the fuel cell controller (PLC) and various sensors.

Based on this data, it must make real-time decisions to optimize performance (e.g., reducing power output if the temperature is too high).

The machine itself makes these decisions (edge computing) and then commands the controllers that manage the energy management system.

The fuel cell itself is controlled by a PLC. However, the energy management system also needs an additional computing system for various tasks, including:

- Collecting and logging data and events from the PLC and additional sensors.

- Processing that data, including computing additional parameters from the available data.

- Visualizing the parameters in a web interface.

- Rule processing, based on configurable rule sets.

- Generating notifications (e.g., via SMS, Email or Telegram) and alarms if an abnormal condition is detected.

- Interfacing the energy management system with its environment. Customers must be able to retrieve parameters, as well as control the power generator (e.g., power it on or off) via various interfaces, including Modbus MQTT or domain-specific protocols like DNP3.

The EMS Challenge

Initially, the GenCell team was very ambitious and inclined to build everything in-house. But soon, the team’s analysis of the risks and efforts quickly led them to abandon the idea. Building from scratch meant significant time and resources spent on commodity features like authentication and communication protocols like Modbus or MQTT.

Realizing the potential setbacks, they pivoted.

GenCell tasked Pluggable with building a new energy management solution that should be more cost effective, more reliable and easily adaptable to future requirements. They started the process by evaluating different software frameworks and we chose macchina.io EDGE.

LOW FOOTPRINT

macchina.io EDGE’s efficiency and low footprint allows the software to run on a low- cost IoT gateway device.

FLEXIBILITY

macchina.io EDGE’s flexibility, adaptability and extensibility allowed GenCell to build a system that best fits their unique requirements.

JAVASCRIPT

JavaScript support in macchina.io EDGE allows the development team to build most of their custom application software in JavaScript.

SUPPORT

The macchina.io EDGE development team helped the project team by building custom features, as well as with troubleshooting.

macchina.io EDGE Features Used

Datapoints

The macchina.io EDGE datapoints engine is used to manage all the data acquired from the PLC, external sensors, as well as any “synthetic” values (computed from other data). The system has 100s of datapoints.

Connectors

Datapoints are made available to external systems via a number of connectors. Connectors are implementations of various communication protocols that directly work with datapoints. No additional coding required.

JavaScript Engine

The JavaScript engine was used to build an event- driven highly flexible rule engine. This makes the system easily adaptable to new requirements, as many aspects of the system can be controlled by configuration data and rule sets, without having to modify the application code.

Protocols & Services

The system also used the protocol and service implementations provided by macchina.io EDGE, including the Modbus TCP/RTU protocol, MQTT, HTTP, as well as support for sending emails and SMS messages.

Web Application Server

The custom web UI of the system is powered by the web application server integrated in macchina.io EDGE.

macchina.io REMOTE Features Used

Remote Access to Web User Interface

macchina.io REMOTE gives access to the web user interface of the IoT edge gateway running macchina.io EDGE and the custom GenCell application. This is available for both end users and support personnel.

Remote Access to System Controller (PLC)

Technicians can connect to the controller of the remote system via macchina.io REMOTE, directly from their service application, for maintenance and troubleshooting.

Remote SSH

Shell access (SSH) to the edge gateway is enabled for troubleshooting purposes, especially during the development phase.

Users and Permissions

Fine-grained control over the devices and ports a user may access.

The Results

macchina.io REMOTE enables seamless secure access to our H2 generators, with automated device registration and connectivity test integrated within our assembly line.

Gal Netzer, GEMS Product Manager GenCell

Using the lean architecture of macchina.io EDGE, we reduced hardware costs by 75%.

- Instead of just a gateway, we delivered a complete energy management system, based on macchina.io EDGE and REMOTE technology, in under a year.

- Possibility to remotely access the local UIs and deeper connectivity (e.g. file transfer via SSH) for technicians. No project delays due to the proven technology of macchina.io.

- Future proof architecture as additional data points and features can be added easily and the solution is ready to use for complex edge computing and IIoT applications within the cloud.

- The edge application manages over 30 system components autonomously and can connect to the internet for data transfer to the cloud and remote management.

Contact us now to future-proof your investment.

Minimize development and operational costs by integrating our highly customizable secure remote access solution.

Reduce software development costs by using our customizable software building blocks that are scriptable with JavaScript.

Reduce hardware costs by using our lightweight, highly scalable and flexible software framework.